HP-14 Schabhobel

Ein echter Hingucker, der die Holzmaserung vor Angst erzittern lässt!

——— John Economaki

Im Jahr 2017 brachte John mit viel Vorfreude den HP-14 Schabhobel an die Öffentlichkeit. Fünf Jahre später haben wir die neuen Designs und Optimierungen in den HP-14 integriert und fühlen uns geehrt, allen Holzbearbeitern diesen brandneuen HP-14 Schabhobel vorzustellen.

Der HP-14 Schabhobel ist durch seine Schneidengeometrie ein spezieller Handhobel, der sich meisterhaft zum Abschaben und Glätten von Oberflächen mit schwierigen Maserungen eignet.

Bei fachgerechter Anwendung des HP-14 Schabhobels können Sie eine glattere Oberfläche erzielen und empfindlichere Materialien schonend bearbeiten. Der Grund dafür ist, dass die Werkzeugschneide schabt und nicht schert. Durch den Einstellwinkel über die Orthogonalität in Abtragrichtung hinaus entsteht ein negativer Spanwinkel. Dieser verhindert ein Zugeintauchen in die Maserung. Es werden in diesem Zerspanungsprozess nur jeweils sehr geringe Mengen an Material abgetragen, was zu glatten Oberflächen führt.

Der HP-14 Schabhobel ist ein Handwerkzeug, das Ihnen bei zukünftigen Projekten viel Freude und Komfort bringen wird.

Klassisches "skelettiertes" Design

Der HP-14 Schabhobel zeigt weiterhin den „skelettierten" Stil des Hobelkörpers, der auch bei den HP-9v2 und HP-12 Hobeln zu sehen ist. Der Hobelkörper ist mit Vorder- und Hintergriff aus Vollmetall ausgestattet und liegt gut in den Händen aller Größen.

Der vordere Griff in Pilzform, welcher durch seine herausragende Ergonomie besticht, basiert auf einer gedrehten Aluminium-Geometrie. Im Anschluss erhält der Formveredelte Körper seine finale Oberfläche durch perlstrahlen und eloxieren.

Der hintere Griff ist aus Rostfreiem Stahl SS304 im Feingussverfahren hergestellt und die beiden inneren Hohlräume sind Schwarz lackiert. Geformt, um die Ideale Vorschubbewegung zu erzeugen. Die hochglanzpolierten, gewölbten Oberflächen bilden einen schönen, reflektierenden Kontrast zu den sonstigen Farben der Hobelkomponenten.

Neu gestalteter Mechanismus zur Einstellung des Messerwinkels

Eine der bemerkenswertesten Neukonstruktionen in der Handhobeltechnologie ist der Hobelmesser-Winkelverstellmechanismus. Die Addition von Lagern mit implantiertem Festschmierstoff eliminieren jegliches „Spiel" im Mechanismus. Dies ermöglicht eine präzise Winkeleinstellung, und somit eine positionsstabile Fixierung des Hobelmessers für optimale Oberflächenqualität am Werkstück.

Breites Spektrum in der Anstellwinkeljustierung

Mit dem Hobelmesser Winkeleinstellmechanismus können Sie Anstellwinkeljustierungen im Bereich von 88°~117° vornehmen. Dies bietet Ihnen die Möglichkeit, verschiedenste Holzarten unterschiedlicher Härte, Rauheit und Maserungform zu bearbeiten.

Feinjustierung der Schabtiefe

Der Anstellwinkel kann über die beiden Rändelmuttern an der Zugspindel feinjustiert und am Gegenlager fixiert werden.

Durch Justierungen in kleinen Schritten, können Spandickenzu- oder Abnahmen im 1/100 mm Bereich erzielt werden.

Das Hobelmesser

Das HP-14 Hobeleisen wird aus gehärtetem Werkzeugstahl mit einer Rockwell-Härte von 58 bis 62 hergestellt. Dadurch eignet sich das Eisen für die Bearbeitung aller Arten von Harthölzern und schwierigen Maserungen.

Die Materialstärke des Hobelmessers beträgt 2,4 mm (3/32“), mit einem angeschliffenen Keilwinkel von 45° was eine ausgezeichnete Schneidenstabilität mit sich bringt.

CNC-gefräster Edelstahl und eloxierte Aluminiumlegierung

Die Geometrie der Hobelsohle, des Hintergriffs und die gesamte Hardware des Hobels wird durch CNC-fräsen des Rohkörpers aus Edelstahl gestaltet.

Der hintere Griff wurde nach ergonomischen Gesichtspunkten entworfen, wobei die Eleganz der polierten Oberfläche erhalten blieb.

Der Messer-Klemmmechanismus, der Mechanismus zur Winkelverstellung und die Seitenplatten sind aus einer CNC-gefrästen Aluminiumlegierung gefertigt. Die Aluminiumkomponenten sind eloxiert, um die Reibung zu verringern, die Härte zu erhöhen und gleichzeitig exquisit auszusehen.

Güteüberwachte Fertigung der Sohlen mit stetiger Prüfung der Ebenheit

Um sicherzustellen, dass der HP-14 Schabhobel eine gleichmäßig glatte Oberfläche auf einem Werkstück erzeugt, wurde der Fertigungsprozess „Herstellung der Hobelsohle“ mit 0,05mm Ebenheit toleriert. Eingehalten werden tatsächlich noch deutlich höhere Genauigkeiten.

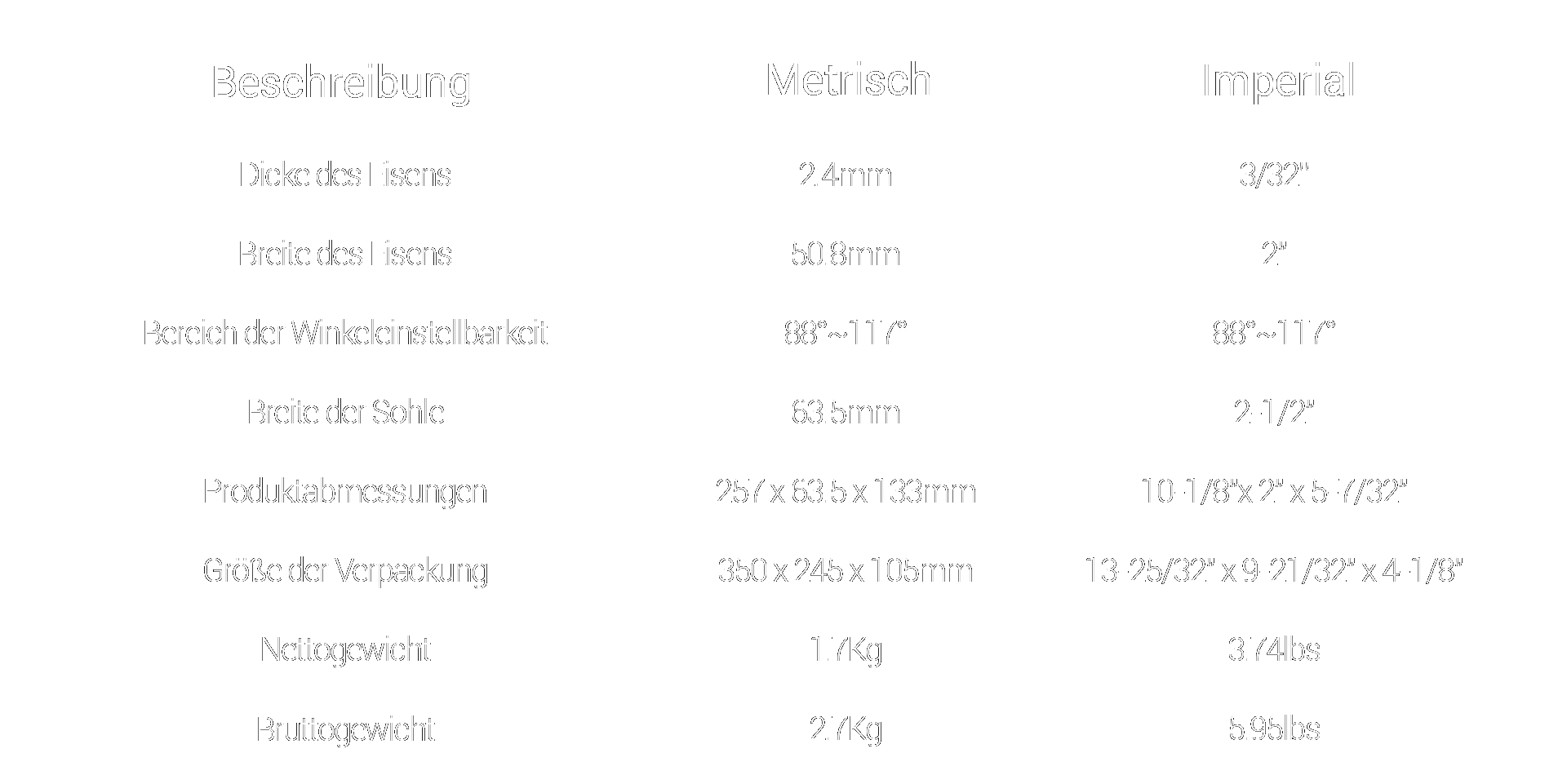

Spezifikation

„Einige Bilder auf dieser Seite sind computergenerierte Darstellungen des Produkts und können von dem tätsachlichen Produkt abweichen. Farben, Texturen und andere Details werden auf den Bildern möglicherweise nicht genau dargestellt. Weitere Informationen entnehmen Sie bitte der Produktbeschreibung und den technischen Daten.“