JMPv2 Jointmaker Pro v2

Das JMP v-2 Schneidsystem verfügt über eine seltsame Schönheit, die einem ans Herz wächst, und das nicht nur aufgrund der Vielseitigkeit.

Denn ja, dieses Produkt ist wie ein U- Boot- es taucht in vielen Holzbearbeitungsanwendungen als „Lösungsbringer" auf.

——JOHN ECONOMAKI

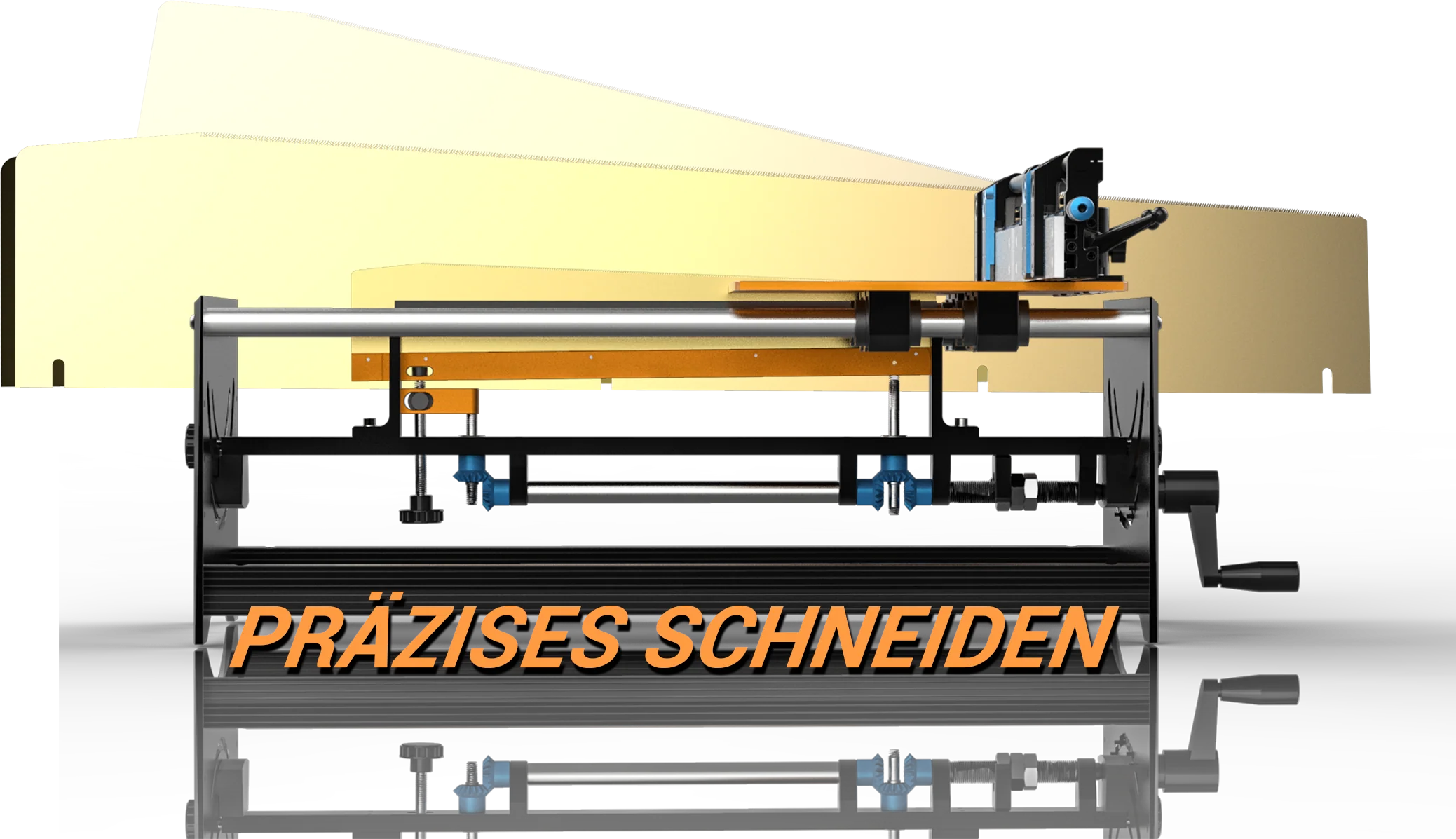

Schneiden, gefertigt in höchster Qualität

Das Kernstück für die hohe Qualität im Prozess ist die Sägemesserschneide. Sie ist der Garant für die extrem hohe Schnittleistung. Würden Sie eine derartige Klinge in eine Handsäge einbauen, wäre das Ergebnis wie der Schnitt mit einer Dozuki- Kappsäge. Die patentierte Schneidengeometrie verfügt an jedem Zahn über 4 einzelne Schliffe, verteilt zu p=28 Zähne / Zoll (Beispiel: Form A)

Mehrere Schneidengeometrien stehen zur Auswahl

Die Messersätze verfügen über 4 verschiedene Schneidengeometrien. Querschnitt A (Standardteil) ist die am häufigsten verwendete Schneide, deren Schneidspalt 0,4 mm misst und auch die meisten Ihrer Schneidanforderungen erfüllt. p= 28z/“. Querschnitt B, p= 32z/“ (optional), Eignung für weiche Hölzer; Querschnitt C (optional), Schneidspalt 0,5mm, p= 28z/“. diese Schneide wurde Schneiden von dichtem Holz entwickelt, Schneide D (optional) p=16z/“ sorgt für einen schnelle Schnitt und einen hochpräzisen Kanten- Abschluss ohne auszufransen. Anwendungszweck: Herstellung von Schwalbenschwanz-Konturen, Zapfen und Bundschlitzen.

Die Schnitttiefen - Einstellung des JMP- erfolgt über eine Handkurbel und ein synchron geschaltetes T-/ Winkelgetriebe, um das Messer bei geringem Kraftaufwand, in seiner vollen Länge auf konstante Schnitttiefe zu justieren.

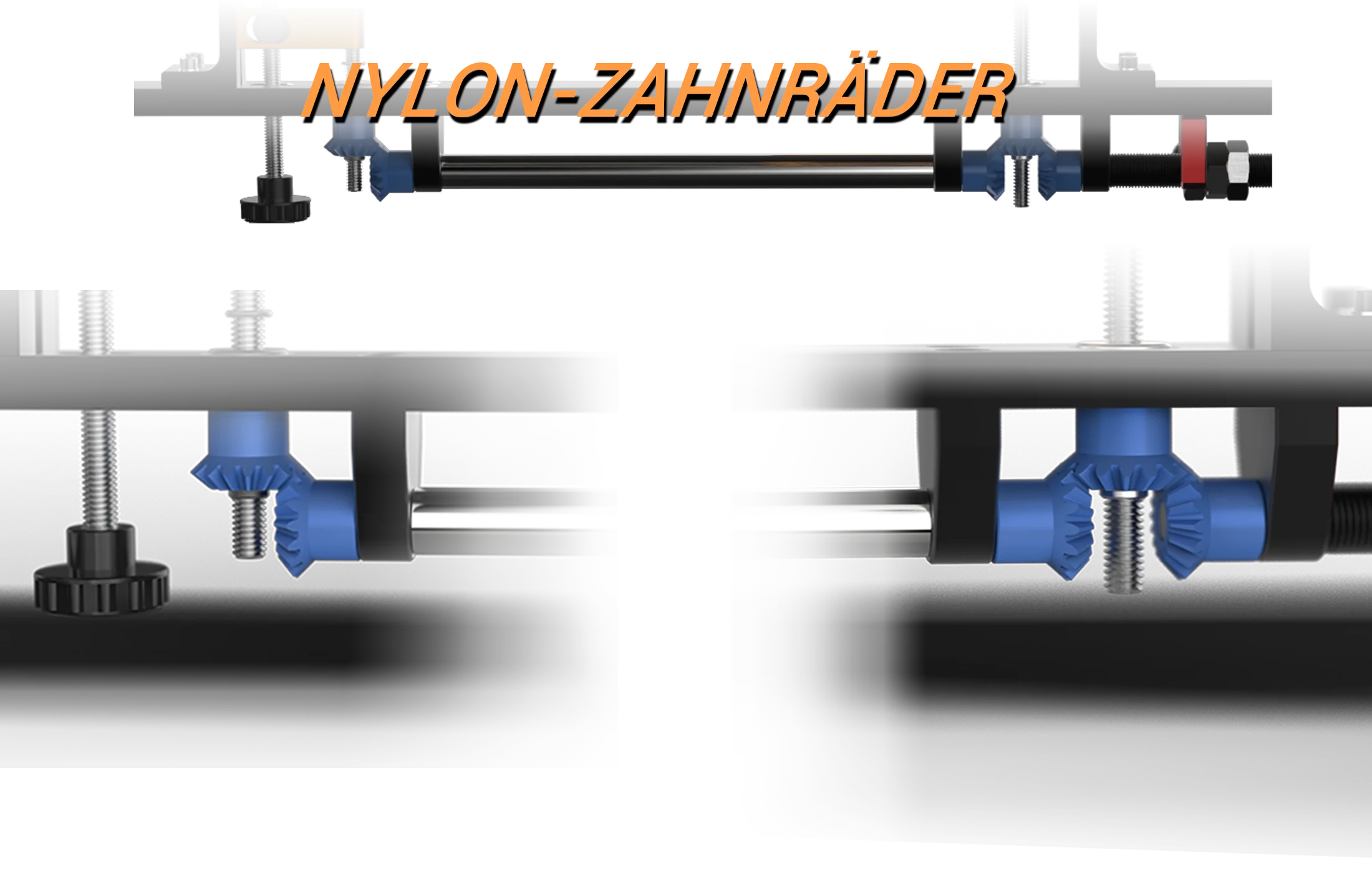

Die Kegelräder des Getriebes sind aus reibungsarmem, Schwingungsabsorbierendem, wartungsfreiem NYLON gefertigt.

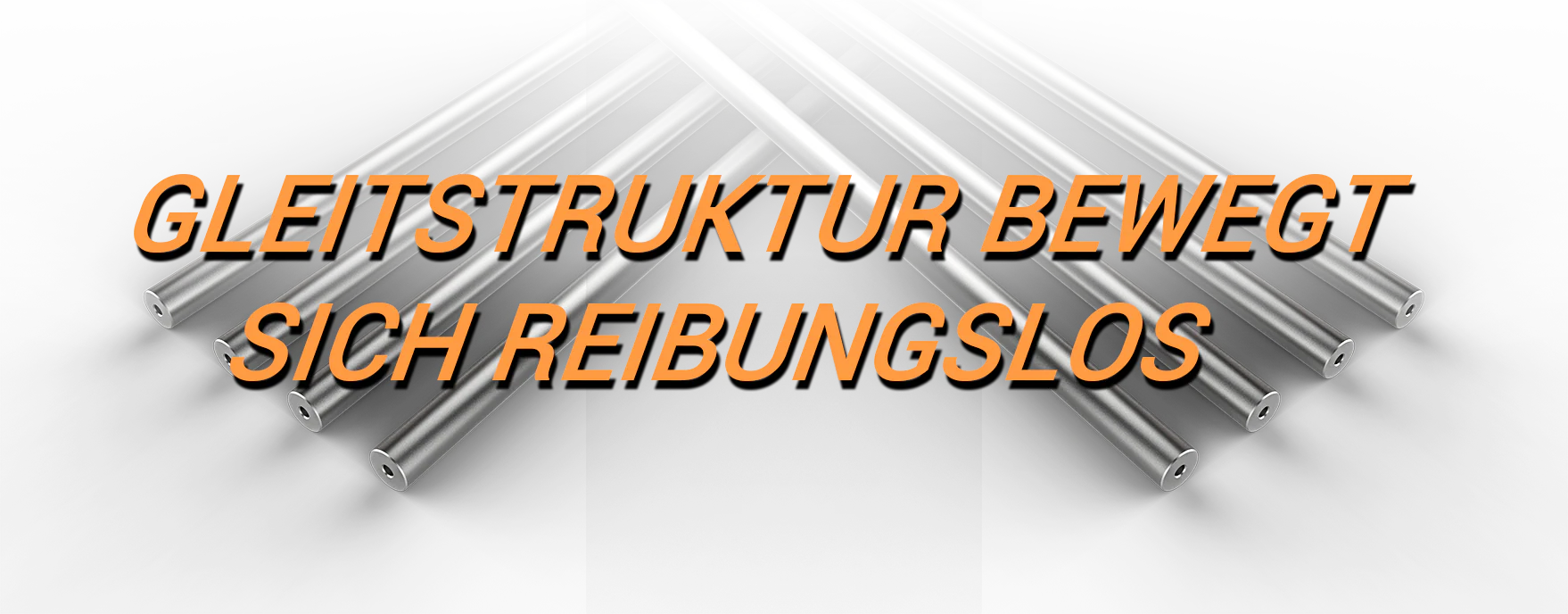

Im JMPv2 kommt in der Vorschubeinheit ein zylindrisches, achsparalleles Linearführungssystem mit wartungsfreien, staubdichten Lagern zum Einsatz. Die Bedienung ist einfach und geräuscharm.

Das Anschlagsystem zur Vorpositionierung und Fixierung der Werkstücke vor dem Schnitt, ist einzigartig, spielfrei und in seinem Handling unerreicht.

Der Tisch gleitet parallel zur Schneide

Die Parallelitätsabweichung in der Gleitrichtung des Tisches zur Schneide liegt unter 0,025 mm. Diese Genauigkeit setzt die Präzision bis hin zum fertigen Werkstück fort.

Ein sauberer und ordentlicher Schnitt kann mit diesem Schiebesystem erzielt werden. Selbst wenn Sie ein kleines Stück Papier neben die Schneide auf den Tisch legen und den Anschlag vor- und zurückschieben, können Sie kein Spiel zwischen dem Papier und der Schneide finden.

Geräuscharmes Linearlager, der Schnitt kann mit einer Hand bedient werden

Linear abgedichtete Acetyl-Lager bieten einen Gleitvorgang mit geringer Reibung, der das Verstopfen durch Staub in den Lagern vermeidet. Der Lärm ist geringer als bei Elektrowerkzeugen. Das Schneiden kann durch Einhandbedienung abgeschlossen werden.

EINFACHE EINSTELLUNG VON SCHNEIDEHÖHE, -WINKEL UND -NEIGUNG

Schneidehöhe und -neigung können über die Kielbaugruppe leicht eingestellt werden

Der Verstellmechanismus der Kielbaugruppe verfügt über Zahnräder mit minimalem Spiel, die nicht nur eine reibungslose Drehung, sondern auch eine genaue Einstellung der Schneidehöhe und -neigung gewährleisten können.

Das Blatt kann über einen Drehzapfen frei geneigt werden

Das Blatt kann über eine Zapfenanordnung bis zu 45° nach links oder rechts geneigt werden. Mit den vier mitgelieferten Anschlägen lässt sich der Neigungswinkel für wiederholtes Schneiden schnell einstellen.

DER HOLZZAUN UND DIE BACKEN

Die Anschläge und Spannbacken sind aus Pappelholz gefertigt. Die Spannbacken können verwendet werden, um das Holzmaterial schnell gegen den Anschlag zu halten, es genau zu schneiden. Es handelt sich um Verbrauchsmaterialien, für die man Ersatz bestellen oder selbst herstellen kann.

SPEZIELLE VERARBEITUNG MIT AUSGEWÄHLTEN MATERIALIEN

Eloxierter Aluminium-Schiebetisch

Die Schiebetische sind aus eloxiertem Aluminium hergestellt, was ihnen nicht nur eine gute Reibungsfestigkeit und hohe Härte verleiht, sondern auch das exquisite Aussehen einer matten Oberfläche.

Zylindrische Führungsstange mit hoher Härte

Die zylindrische Führung besteht aus 40Cr-Stahl, T235 gehärtet und angelassen. Nach dem Verchromen ist die Oberfläche der Führungsschiene blank, gut aussehend, rostfrei und hart.

Japanische Schneide hoher Qualität

Die Zähne der Schneide werden mit einer Hochfrequenz-Wärmebehandlung bearbeitet, so dass sie eine hohe Härte und eine ausgezeichnete Schneidleistung aufweisen, die einen feinen Schnitt in verschiedenen weichen und harten Hölzern ermöglicht.

Bilder von Anwendungsbeispielen

Der Jointmaker Pro v2 ist ideal für:

• Box-Macher

• Musikinstrumentenmacher

• Architektonische Modellmacher

• Spielzeugmacher • Bildeinrahmer

• Möbelbauer Makers • Künstler

• Hobbybastler • Modelleisenbahn-Bauer

• Modellbauer

• Umweltbewusste Holzverarbeiter

• Professionelle Holzbearbeiter

• Studios für Spezialeffekte

• Schulen

• Parkett

• Puppenhausmacher ...

DIE EINZIGE GRENZE IST DIE EIGENE VORSTELLUNGSKRAFT!

SPEZIFIKATIONEN

Standard-Teile

Optionales Zubehör

Problembehebungen

„Einige Bilder auf dieser Seite sind computergenerierte Darstellungen des Produkts und können von dem tätsachlichen Produkt abweichen. Farben, Texturen und andere Details werden auf den Bildern möglicherweise nicht genau dargestellt. Weitere Informationen entnehmen Sie bitte der Produktbeschreibung und den technischen Daten.“